Whatever brand of cars you’re into, it’s all about the driving experience once the car is on the road. Driving in comfortable and supportive seats are as important as looking correct.

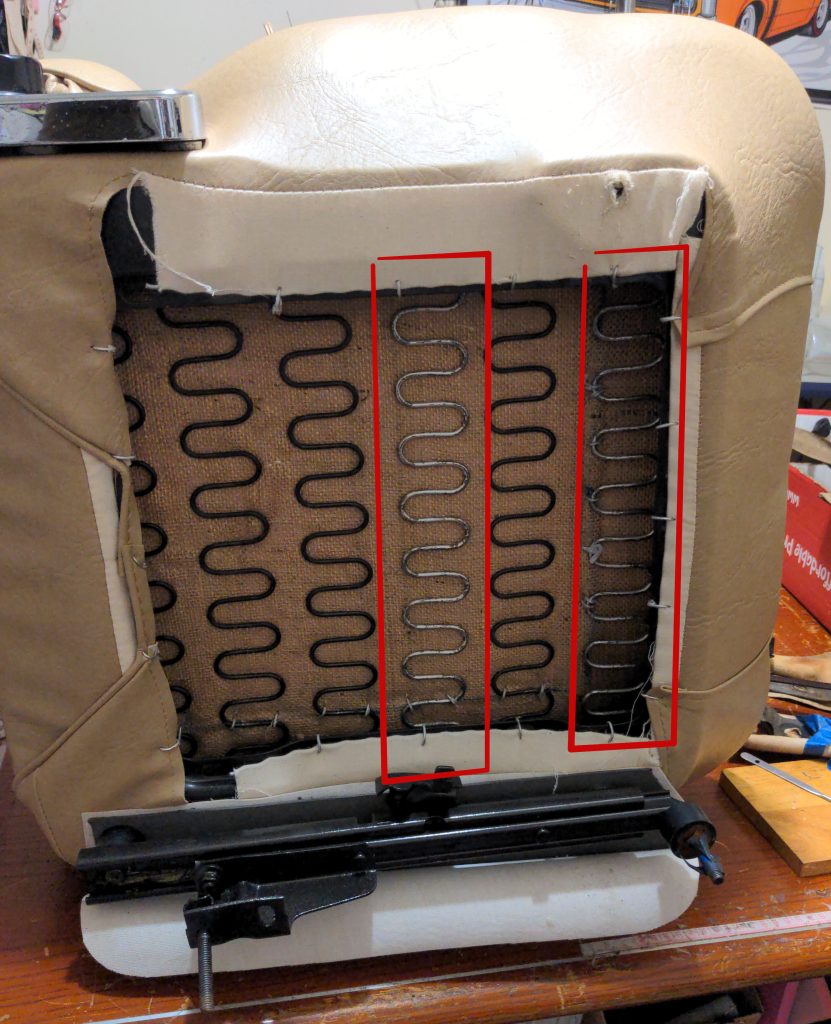

After stripping down, inspecting and fixing so many different seats, we found the happy recipe to great driving seats is fix the seats right from the foundation.

Our goal is to properly restore seats so that the cars get the love and attention they deserve.

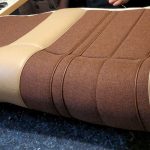

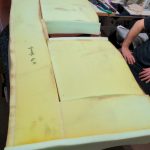

New Seat Foam and Skin Development

New seat skins cannot be properly developed without developing correctly sized foam. Foam comes in predetermined thicknesses and in a range of weight, quality etc. Commonly used foam thicknesses in car seats are 25mm, 50mm etc. That’s why by dissecting old factory foam and doing a bit of recovery work, we can learn what thickness and type of foam factory used. This can then be replicated, hence correct spec foam can be developed. New seat skins then get developed in reference to original factory seats (reconditioned, new springs put in where needed etc.), with new seat foam installed. For new models, we whip up mock up seat skins that allow us to check not just the sizing of the seat trim, but also double check our foam. The mock fitment would then show us where we need to improve our foam kit and/or seat skins. Our goal is to make foam kits and seat skins that are better than factory.